Heat sinks are an important part of electronic devices. This explains why they’re commonly used and designed uniquely for optimum functionality. During the selection process, most people make mistakes that should be avoided at all costs.

This can only be true if the person doing the selection understands factors that impact heat sink performance. These include considerations in heat sink design that must be considered. At the end of the day, the future of electronics is still in the hands of these tiny devices.

How to improve the performance of the heat sink

In one ‘Do it Yourself’ forum, Mr Lukas improved the performance of his heat sink using hydrochloric acid. He says it worked well and that it’s worth a try. The acid made the surface of the heat sink more rugged. This helps create a micro-turbulence that increases the performance of the heat sink.

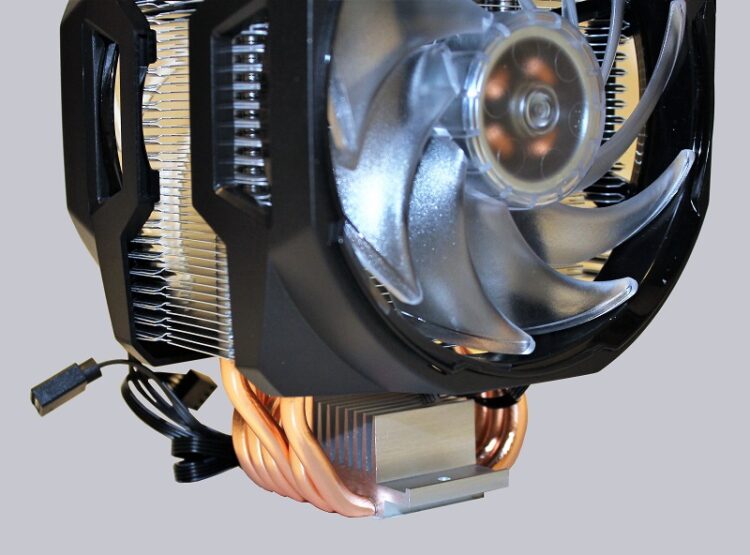

The fins in a heat sink play a major role in its performance. That explains why you should mount it in the right manner. In most cases, you should mount the fins in a vertical way for better performance.

The vertical positioning of heat sinks improves airflow. Remember that proper airflow is responsible for most high-performing heat sinks. This, it does, using low voltage. This means, that lesser heat will be produced in the process.

Some experts also advise that you reduce the size of the fan to increase productivity. Besides, you should try all you can to release the trapped air. This will allow for proper flow and your heat sink will do better than before.

Considerations in Heat Sink Design

Heat sink performance is dependent on the design. Here are some important considerations when designing a heat sink.

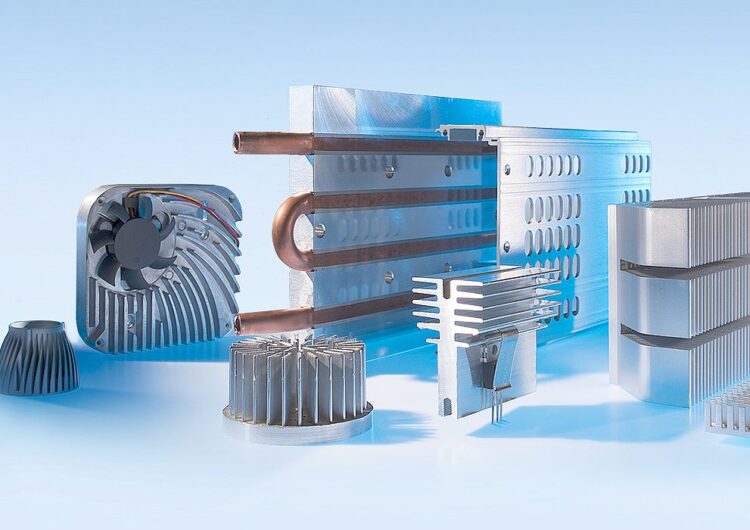

1. Natural/forced convection

Heat sinks are said to be more productive when you have the perfect balance of natural and forced conventions. If left to work in an uncontrolled environment, heat sinks will work just fine. But it may work better if the environment is tactfully enhanced to increase productivity.

While heat sink fins work to increase the amount of heat removed from the environment, a fan makes things even better. It increases the amount of heat sent to the fin for maximum dissipation. The fan also provides an environment where the air is not restricted. As a result, more heat is sent out of the device.

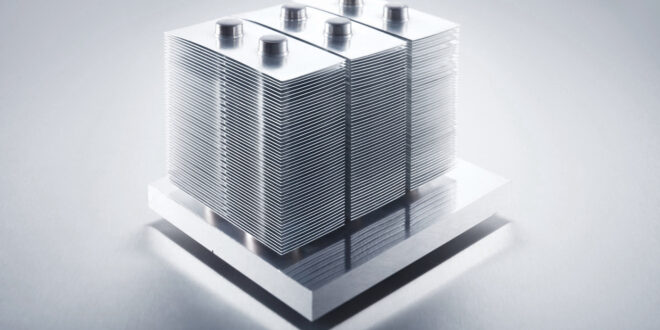

2. Material selection

There are two major options for which material to work with when designing a heat sink. Copper is highly rated but more expensive than Aluminium. When producing heat sinks in large numbers, it’s prudent to go for the cheapest yet delivers great value for money. This makes Aluminium a reasonable choice to go for. Click FONNOV ALUMNIUM, you can find a wide range of aluminium heat sinks.

3. Fan and fin sizes

Fins work well to increase the amount of heat released. Fans also support fins when doing the work. The bigger the fan and fins, the better the work done. But you cannot build very big fans and fins and put them in tiny electrical devices. Not only will they make the device heavier but also will require you to have much more space to accommodate the features.

4. Calculations to size a heat sink

These must be well done to increase productivity. A lot of physics apply in the operations of heat sinks. You must know the numbers involved and calculate what suits your design the most. In many cases, the goal of these calculations is to increase efficiency.

How to Select a Heat Sink

1. Product size

Heat sinks are designed in different sizes. The bigger ones tend to be more powerful and efficient. But the selection is subject to the size of the product in question.

A smaller-sized product will accommodate a smaller heat sink. This means you’ll have no other choice than go for a smaller heat sink. A bigger heat sink will do for a larger-sized product.

Larger electronic devices also tend to produce more heat. To deal with that effectively, you’ll need a bigger heat sink with more fins and a bigger fan. That way, the amount of hot air taken care of will significantly increase.

2. System cost

Costs are an important consideration when choosing a heat sink. Cheaper heat sinks will work better for cheaper devices. Besides, it’s more economical and will increase your profit margins for manufacturers.

Every item used to make a heat sink costs money. Therefore, bigger heat sinks will most likely cost more money. This explains why some manufacturers opt to make smaller heat sinks to fit their budgets.

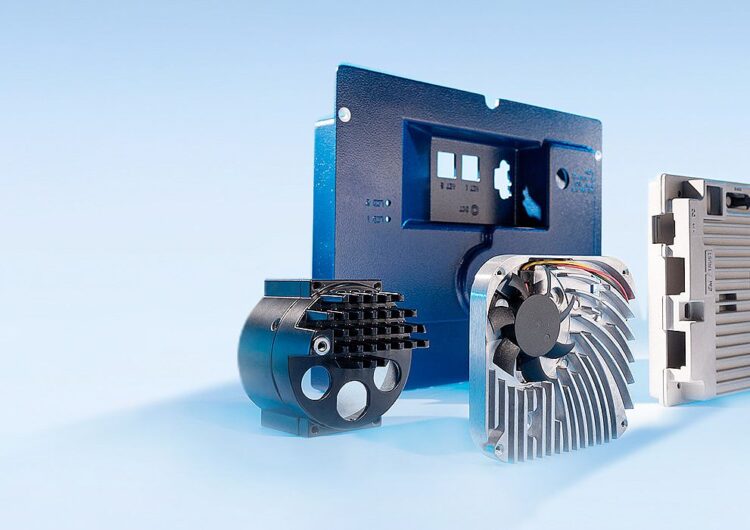

3. More cooling options

Heat sinks work better with enhanced features. Therefore, you should go for those with as many cooling options as possible. The options give the sink more power to dissipate more heat. That way, the device in consideration will perform better because more heat is released into the environment.

Mistakes made when selecting a heat sink

Man is to err and therefore we’re bound to make mistakes. When it comes to making or selecting a heat sink, we can make mistakes. Some can be costly while others won’t cost you that much. But the best thing to do is to avoid these mistakes whether they’re costly or not. Here are some of the mistakes made when selecting a heat sink.

1. Over relying on the surface area when selecting a heat sink

Many have associated better heat sink performance with the surface area. Well, this can be misleading. The surface has a big impact on the delivery of a heat sink but shouldn’t be the sole factor when selecting a heat sink. There’s a myth that most people have been made to believe that by only increasing the surface area of a heat sink you increase the performance. That’s not entirely true.

Other than the surface area of a heat sink, a lot of other factors come to play. That’s why you need to know that performance of the heat sink is enhanced by a combination of factors. Surface area is one of them but not the only one.

Many platforms have used surface area calculations to show how an increase in the surface area also increases the performance of heat sinks. While that’s true, it’s not correct to believe that’s the only way to enhance the device’s performance.

2. Over relying on thermal resistance to determine performance

Again, most people use thermal resistance to predict a heat sink’s performance. While it might be a good indicator, it’s important to note that it’s not the most accurate prediction method. That’s why one should consider other options. That way, you can more accurately determine your heat sink’s performance.

3. Poor material selection

Aluminium and Copper both have different properties. For that reason, you have to know when to choose copper and not Aluminium. You have to understand when to go for Aluminium and drop Copper. This is because these materials perform differently when under certain conditions.

Hi Boox Popular Magazine 2024

Hi Boox Popular Magazine 2024