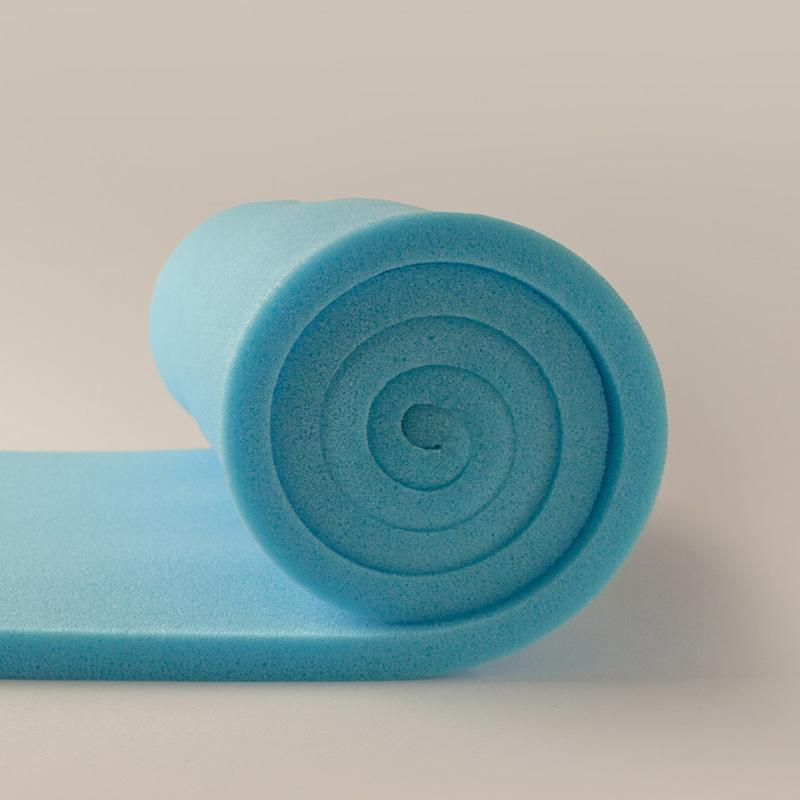

High-density foam, particularly in the 1-4 density range, is a critical material in various industries, from furniture manufacturing to automotive applications. Its unique properties, including durability, firmness, and resilience, make it a preferred choice for applications demanding longevity and comfort. Understanding the nuances of this material is essential for professionals in related industries and consumers looking for high-quality foam products.

Composition and Properties

High-density foam, specifically in the 1-4 range like in Midwest Fabrics, is made from polyurethane, a type of polymer. It’s crafted by combining polyols and diisocyanates, two chemicals that react to form a flexible, durable material. The density of foam, measured in pounds per cubic foot (PCF), indicates its mass per unit volume. The higher the density, the more material is packed into each cubic foot, resulting in greater durability and support.

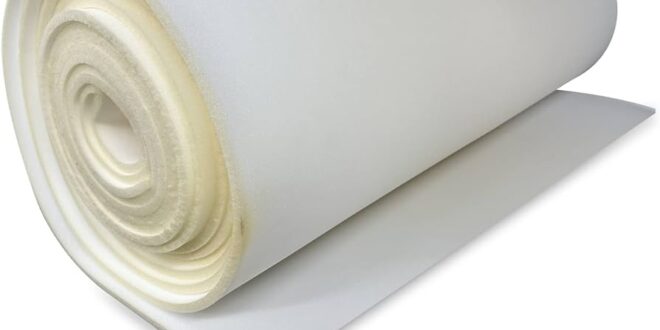

Manufacturing Process

The production of high-density foam involves several steps. It starts with the mixing of raw materials, followed by a foaming process where air or gas is introduced to create a cellular structure. This foam then goes through curing, where it hardens and becomes more resilient. Cutting and shaping are the final steps in manufacturing foam products, tailored to specific applications and dimensions.

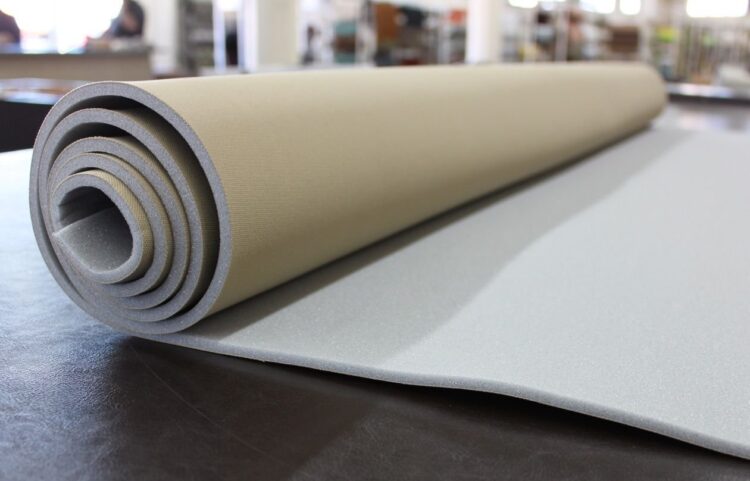

Applications and Uses

1-4 high-density foam is versatile. In furniture, it’s used for cushions and mattresses, offering comfort and support over prolonged use. In the automotive sector, it’s applied in seating, insulation, and soundproofing, thanks to its durability and ability to absorb impact. It’s also used in packaging, especially for delicate or heavy items, where its density provides excellent protection.

Benefits and Advantages

The primary benefits of 1-4 high-density foam include its longevity and resilience. It retains shape over time, even under constant weight and pressure. This feature is crucial in furniture and bedding, ensuring comfort and support over the years. Additionally, its shock-absorbing properties make it ideal for protective packaging and safety-related applications in various industries.

Environmental Considerations

While high-density foam offers numerous benefits, environmental impact is a concern. Polyurethane foams are not biodegradable, and their production involves chemicals that can be harmful if not managed properly. However, the industry is evolving, with manufacturers increasingly focusing on recycling and using more sustainable production methods.

Quality and Performance Standards

When selecting 1-4 high-density foam, it’s essential to consider specific quality and performance standards. These standards ensure the foam meets certain criteria for durability, resilience, and safety. For instance, certifications like CertiPUR-US in the US assure consumers that the foam is made without harmful chemicals and meets strict environmental and health standards. Additionally, performance tests like indentation force deflection (IFD) measure the firmness of the foam, indicating how much pressure is required to indent the foam by a certain percentage of its thickness. Understanding these standards helps in choosing the right foam for specific needs.

Conclusion

1-4 high-density foam is a material with a wide range of applications, known for its durability, support, and versatility. Its manufacturing process, while complex, results in a product that plays a crucial role in various sectors. As we move towards more sustainable practices, the high-density foam industry is adapting, ensuring that this essential material remains a mainstay in manufacturing and product design, balancing performance with environmental responsibility.

Hi Boox Popular Magazine 2024

Hi Boox Popular Magazine 2024