Many manufacturers enter into the world of Computer Numerical Control (CNC) in an attempt to automate their production line. While CNC machines are integral to automated production, they cannot complete a fully automated process on their own. Enter: CNC robotics. Find the key to full automation on this page as we discuss the history, powerful impact, and role of robotics of CNC machines.

Tell Me More about CNC Machines

Computer Numerical Control has been around for quite some time. In fact, we can look all the way back to the early 1800s to discover its origin. Joseph Marie Jacquard had no idea how far his innovation would come when he figured out how to control a weaver with a simple punch card. Each hole represented an action while the non-holes told the machine no actions.

While many horrendous patterns were woven into a variety of textiles after Jacquard’s discovery, the ability to automate machines was an invaluable find. The weaver was the first CNC machine – a machine capable of performing a programmed function without being manually operated.

Fast forward a century or so and the next major achievement in automation was born. The automation banner used metal cards to help produce airplane propellers. As you can imagine, the time period demanded excellence and innovation from those working in manufacturing. The 1940s represented a time of progress by the necessity for several countries around the globe.

The wartime of the 40s led to new ideas moving forward. Large companies like GE and IBM latched on to these methods of automation. The myriad CNC machines we see today were born of those early ideas to improve textile options and make manufacturing more efficient in a time of need. As technology improved and computing came to fruition, improvements were made to CNC machines, as well.

The Impact of the CNC Machine on a Changing World

If you step back and take a broad look at the technological development since Jacquard made his punch cards, you will be astonished. The train, plane, and automobile have all joined our world since then. Not to mention things like cell phones and computers. CNC machines have played a massive role in these changes.

As the world wanted speed, the CNC machine provided it

If you needed something like a horseshoe, you had to wait for your blacksmith to make it. Assuming your town had enough blacksmiths, you might get that shoe on your horse in a few weeks. Imagine if you had to wait weeks to replace that flat tire. Like Veruca Salt in Charlie and the Chocolate Factory, you want it now!

The CNC machine has made it possible to have what you want when you want it. Without them, Amazon would have warehouses full of barren shelves as they wait for handcrafted products to be made.

Also read: CNC machining service

Products you can trust

Quality and consistency are two characteristics we expect from the products we buy. If we like something, we purchase it, again and again, knowing that it will be enjoyable each time we get it. The CNC machines make this possible. Otherwise, handmade products can vary depending on who makes them and what mood they were in when they did it.

Dependable…and affordable?

When you see “handmade” on an item, what is the first thing that comes to mind? Expensive! The CNC machine and its automation make it possible to streamline production. This streamlining makes things faster and makes manufacturers capable of outpacing demand. If supply is ahead of demand, prices come down. Voila! CNC machines have made your needs more affordable.

Safety first

Think of all the things involved in metalwork, for instance. Torches, sharp blades, heavy metal. The CNC machine takes many of those risks out of the equation for workers. Manufacturing has become safer due in large part to these machines. The machines themselves are often made safe with protocols like fencing, soundproofing, and hard stop buttons.

No One Machine to Rule them All

Most CNC machines perform one task with excellence. Those that multitask can be expensive, challenging to upkeep, and can be difficult to place in certain manufacturing settings. Fortunately, CNC machines can be used in conjunction with each other to create a powerhouse of productivity. Here are some samples of typical single-task CNC machines found in many manufacturing facilities and ideas of how robotics have improved them:

A Driller is a machine that puts a drill in position while holding the material to be drilled. In some settings, a human is tasked with placing the material in the machine and changing out drill bits. This is where we begin to see robotics take part in the process to create truly automated facilities – the robotic arm. The arm can place the material accurately and communicate directly with the CNC machine to ensure the proper drill position.

Welding may look fun with all the sparks flying and such. It is one of the most dangerous jobs found in manufacturing. CNC machines have helped reduce the dangers of welding but there are still risks involved. A CNC robotic machine can step in to protect your workers while producing a near-perfect product.

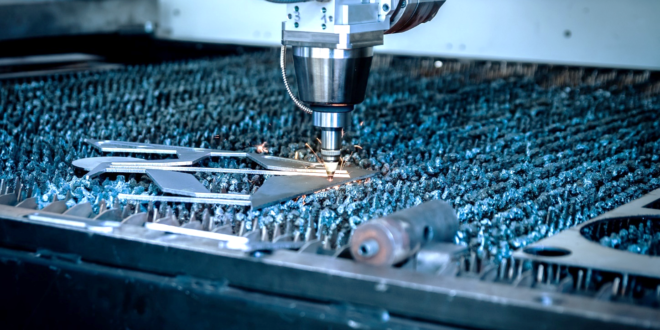

A plasma cutter can be a site to see for anyone who needs precise cuts on materials that saws cannot match. As its space-age name implies, it needs lots of room and safety precautions to be operated without injury. Sparks fly off, gases build-up, and fire danger is always present. Have no fear, a robotic arm is here! The robotic arm stands in the face of danger so a human operator does not have to.

Grinding and lathing are similar jobs performed admirably by standard CNC machines programmed to certain shapes. In grinding, the wheel typically moves around the shape while lathing rotates the part against the wheel.

A miller can cut most materials into a specified shape. Traditionally, the human operator would feed whatever material into the machine. This type of repetitive work is bad for the body over time, leading to issues like arthritis, chronic pain, and other potentially debilitating problems. A robotic arm can step in and load the machine quickly while avoiding rest times and painful injuries.

We spoke a little bit about the complexities of a multitasking CNC machine. They are expensive and quite difficult to operate or train new operators to control. It is far easier to program a robotic system to take the place of a human operator. While transforming material to finished product with one machine is difficult, it can be done when combining robotics with CNC machinery.

CNC machines are placed into categories based on more than just their main job. Another defining factor is how many axes the machine moves on. Early CNC machinery used two-axis like up and down or forward and back. As technology improved, we have moved onto multiple axes – even up to seven, which is vital in the world of 3D tooling.

Accuracy is another factor in defining CNC machines. As you can imagine, this is an important factor in deciding what CNC machine is right for you. As for accuracy increases in grade, you can usually assume robotics and advance programming is involved. Grades range from normal, to high, to ultra-precise.

Finally, CNC machines are grouped into two main categories: semi-automatic and automatic. The former group relies on human and robotic functions like loading materials, physical control of the machine, taking materials off the machine, and quality control.

Automated CNC machines use the machine combined with robotics to create an efficiency monster. CNC technology is amazing in and of itself, but when combined with advanced robotics cannot be rivaled. Robotics takes humanity out of the process. This means fewer mistakes, less danger, and no vacations!

A CNC machine can be paired with multiple robotic arms and programmed to be under the complete control of automation. Errors, injuries, and downtime be gone!

Automation in Review

| CNC Machine Alone | Robotic Arms |

|

|

|

|

|

|

Hopefully, you are not interpreting all this valuable information as a slight against CNC machines. These machines have altered the very course of humanity! The point is to impart the importance of robotics to the future of CNC machining in manufacturing. Robotics can take CNC machines to the next level by adding full automation.

Let’s look at how a robotic arm can add to the already impressive output of CNC machines:

First, the arm picks up the material and places it in the machine. It puts it in the right place every time and never stops until you want it to. Next, the robotic programming closes the door to the machine and directs the operation to start. The CNC machine does the hard work of production while another robotic arm awaits its finish. Finally, a robotic arm takes the finished product from one machine and places is it in the next, can inspect it, or package it for shipment.

You might be asking how this robotic process is better than a traditional human-operated CNC machine. It is more efficient, lacking the need for breaks and time off. It is faster, as humans tend to vary pace over time due to mitigating factors like mood, fatigue, or illness. It is more accurate, as the robotic arm does what it is programmed to do without variance. It is safer. Robots do not suffer hearing loss from loud machines, muscle tears from overuse, or respiratory issues from particulates in the air. A robotic arm is capable of multiple jobs at once, meaning while the machine is working the arm can be prepping the next piece or performing another job altogether.

Choices, Choices

Great. I have convinced you that a robotic arm is a right choice to improve your manufacturing workflow. Now your next step is to choose the appropriate equipment. Here is an example of two choices from Rozum Robotics for you to grasp what you should be comparing:

| Consideration | Rozum Robotics Pulse 90 | Rozum Robotics Pulse 75 |

| Reach (how far it can reach) | 900 millimeters | 750 millimeters |

| Payload (how strong it is) | 4 kilograms | 6 kilograms |

| Degrees (how flexible it is) | 6 degrees | 6 degrees |

| Repeatability (how exact it is) | 0.1 millimeters | 0.1 millimeters |

| Temperature (where it works) | 0 – 35 Celsius | 0 – 35 Celsius |

| Weight (how heavy it is) | 13.6 kilograms | 12.6 kilograms |

| Non-stop (work with no breaks) | 20,000 hours or more | 20,000 hours or more |

| Warranty | 1 year | 1 year |

| Price Point (the bottom line) | $25, 864.00 | $21, 839.00 |

On this page, you can find more parameters for comparing

Everything on this page should have shown you the value of adding robotics to your CNC machine operation. The only thing better than good technology is a great technology. An easily installed, the efficient robotic arm can change your workflow in ways you never thought possible while reducing overall costs and stress.

Robotics is certainly the future but it is also the now.

Hi Boox Popular Magazine 2024

Hi Boox Popular Magazine 2024