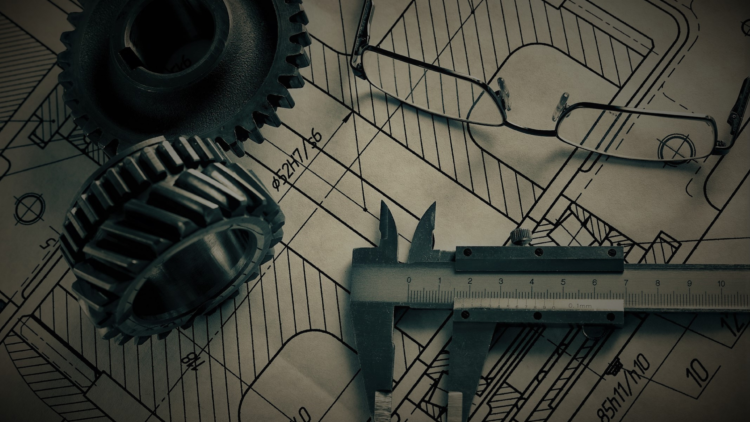

Step into the fascinating realm of machining designs, where the art of shaping our world reaches extraordinary heights. From the earliest tools crafted by our ingenious ancestors to the cutting-edge machinery of today, these designs have played a pivotal role in transforming raw materials into intricate and indispensable products.

Delving deep into the realm of precision cutting, shaping, and forming, machining designs serve as the building blocks upon which countless industries and technological marvels have flourished.

Throughout the annals of history, it is the brilliantly simple and elegantly ingenious machining designs that have left an indelible mark. Seemingly unassuming at first glance, these designs have spurred revolutions in industries, supercharged productivity, and opened up limitless possibilities for human achievement.

By embracing the power of simplicity, these visionary designs have redefined manufacturing processes, revolutionized efficiency and reshaped the very fabric of our existence. Join us as we embark on a captivating journey of unraveling the stories behind these extraordinary designs and the profound impact they have had on our world.

How Machining Designs Steered the Course of History

From the dawn of civilization to the cutting-edge modern era, the influence of machining designs has been nothing short of transformative. Picture the early days when ancient humans skillfully crafted tools from stone, bone and wood, propelling advancements in hunting, agriculture and construction.

As civilizations advanced, the art of metalworking emerged, leading to remarkable achievements by pioneering cultures like the Egyptians, Greeks and Romans.

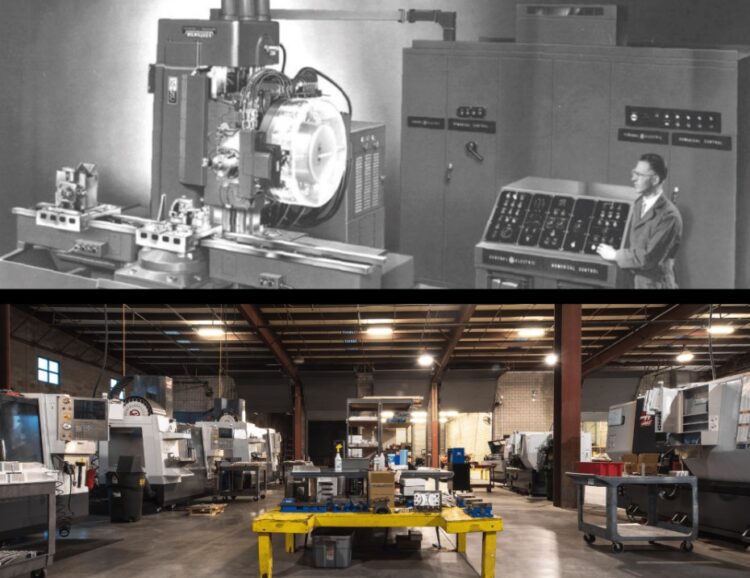

Fast forward to the Middle Ages, an era that witnessed the birth of water-powered mills, an innovation that forever changed the trajectory of production processes and set the stage for the magnificent Industrial Revolution.

It was during this epoch that the lathe, a groundbreaking machining tool enabling rotational cutting and shaping, took center stage. The Industrial Revolution itself heralded a new era in manufacturing, introducing awe-inspiring machine tools like the screw-cutting lathe and milling machine.

One of the most pivotal breakthroughs in the history of machining was the advent of interchangeable parts in the late 18th century. This magnificent feat of precision engineering revolutionized production by allowing standardized parts that seamlessly fit together, facilitating easy assembly, repair and replacement. The ripple effect of this innovation was nothing short of extraordinary, paving the way for mass production on an unprecedented scale and fueling the fires of progress.

These defining moments laid the foundation for the rise of remarkable machining designs, which exuded simplicity while wielding unimaginable brilliance. These designs championed precision, standardized processes and uncompromising efficiency, serving as the catalysts for transformative innovations that reshaped industries and propelled humanity into uncharted territories.

Even today, their impact reverberates through the corridors of progress, as machining remains at the forefront of technological advancements and industrial breakthroughs.

Swing Check Valves Reinvented Fluid Control Systems

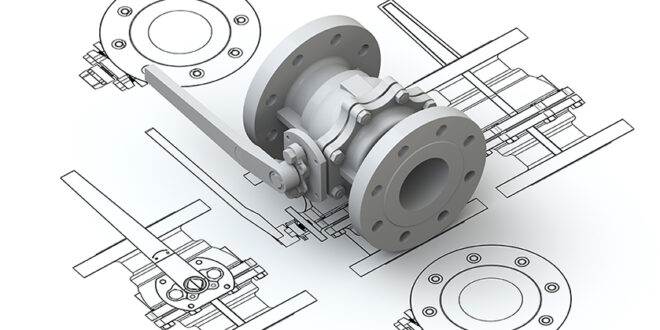

One of the shining examples of enduring designs are swing check valves, a testament to the fusion of history and modernity. With a rich legacy and ubiquitous usage in fluid control systems spanning industries such as oil and gas, water treatment, chemical processing, and power generation, these mechanical marvels have firmly established their indispensability.

Born during the Industrial Revolution, swing check valves boast a brilliant configuration, consisting of a hinged disc seamlessly connected to the valve body. This ingeniously simple design allows fluid to flow in a singular direction while deftly preventing backflow by swiftly swinging closed when required.

While swing check valves seamlessly minimize pressure drop and facilitate unimpeded flow, they do occasionally give rise to water hammer, potentially causing pressure surges and damage. To conquer this challenge, modern adaptations have been introduced, incorporating dampeners to regulate the valve’s closing speed and effectively absorb kinetic energy.

Tailored to meet diverse needs, swing check valves are available in an array of sizes, materials, and configurations. From cast iron to steel, stainless steel, and alloys, these valves cater to every industry’s unique requirements.

Their inherent versatility allows for flexible installation, be it horizontal, vertical, or angled, seamlessly adapting to the layout of the specific system. With their simple yet robust design, swing check valves continue to play a pivotal role in fluid control, celebrated for their unwavering reliability and effortless installation across industries worldwide.

The Interchangeable Parts System Revolutionized Mass Production

The interchangeable parts system has revolutionized manufacturing by enhancing efficiency, maintenance, and mass production. Introduced in the late 18th century, it standardized components that could be easily swapped during assembly. This concept, pioneered by Eli Whitney in firearm production, marked a major manufacturing breakthrough.

Standardized parts greatly improved efficiency by streamlining assembly. With interchangeable components custom-made parts became obsolete, leading to faster production processes. Maintenance and repairs also became more convenient.

Identical parts could replace faulty components swiftly, reducing downtime and costs. The interchangeable parts system also enabled mass production. Manufacturers could now produce components in large quantities, ensuring seamless integration and efficient assembly.

Over the years industries across the board have embraced this system. Automotive manufacturers achieved efficient assembly lines and simplified repairs, while machinery production scaled up, thanks to standardized parts. Electronics, appliances, and furniture industries have also massively benefited from the system. Quick assembly, customization, and improved customer satisfaction have become a reality.

The interchangeable parts system has completely transformed manufacturing. Standardized components have enhanced efficiency, maintenance, and mass production, and most industries, from automotive to electronics, continue to reap the rewards of this revolutionary design, driving progress and innovation.

Final Words

The remarkable influence of machining designs on human civilization and the creation of intricate products cannot be overstated. Innovations such as the awe-inspiring lathe, the ingenious swing check valves, standardized screw threads, and the transformative ball bearings among others have ignited revolutions in manufacturing, catapulting precision, efficiency, and durability to new heights.

From simple designs like the screw thread and ball bearing, and all the way to the modern-day marvels, we witness the unrivaled power of these designs, streamlining production, reducing friction, and revolutionizing machinery and transportation.

Never underestimate the potential of seemingly modest designs, for they possess the uncanny ability to drive profound change. By augmenting efficiency, ensuring durability, and championing precision, these designs have unlocked untold possibilities, leading to cost savings, technological breakthroughs, and a brighter future for humanity.

As we embrace the relentless pursuit of innovation and nurture the flame of creativity, the boundaries of machining design will continue to be pushed, opening up new frontiers and forging a path to an extraordinary tomorrow. Let us stand united, fueling the fires of innovation, and embracing the limitless potential of machining design for a world that knows no bounds!

Hi Boox Popular Magazine 2024

Hi Boox Popular Magazine 2024