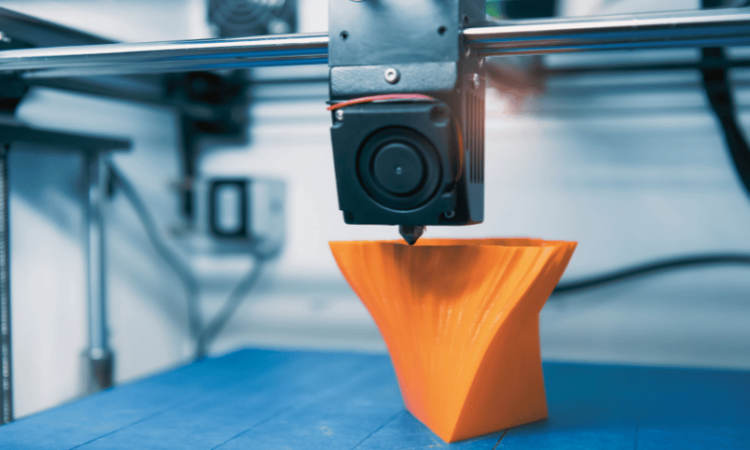

In today’s rapidly advancing world of 3D printing, technology has become more accessible than ever before. With its ability to bring ideas to life and revolutionize various industries, 3D printing is a valuable tool for creators, engineers, and hobbyists alike. However, the cost of materials, especially filaments, can quickly add up and become a significant barrier for those on a tight budget. Fear not, though, as we have compiled a comprehensive guide to help you navigate the world of budget-friendly 3D printing in 2024. Let’s explore various strategies to save money without compromising on the quality of your prints.

Understanding filament types: PLA, ABS, PETG, and more

Filaments are the lifeblood of any 3D printing service. Understanding the different types available can help you make informed decisions when it comes to both cost and quality. PLA (Polylactic Acid) is one of the most popular filaments due to its affordability, ease of use, and wide range of color options. ABS (Acrylonitrile Butadiene Styrene) offers durability but comes at a slightly higher price point. PETG (Polyethylene Terephthalate Glycol) strikes a balance between PLA and ABS, providing strength and flexibility. Researching fiber types will ensure you select the most suitable option for your specific project needs and budget.

Comparing filament prices: Finding the most affordable options

With the growing popularity of 3D printing, the market is flooded with filament options from various manufacturers. Comparing prices across different brands and suppliers can save you a significant amount of money. While it may be tempting to opt for the cheapest option available, it’s important to consider factors such as fiber quality, diameter consistency, and customer reviews. Look for reputable brands that offer a good balance between affordability and quality.

Utilizing recycled materials: Eco-friendly and cost-effective solutions

In an era where sustainability is a top concern, using recycled materials for 3D printing is both environmentally friendly and budget-conscious. Some companies specialize in producing filaments from recycled plastics, such as PET bottles or industrial waste. These recycled fibers often offer comparable performance to their virgin counterparts at a fraction of the cost.

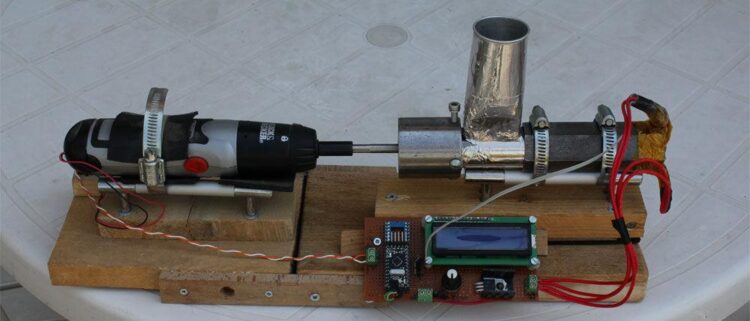

DIY filament production: Making your own filaments at home

For the adventurous makers and tinkerers, producing your own filaments at home can be a rewarding and cost-saving endeavor. Filament extruders allow you to transform plastic pellets or even failed prints into usable fibers. While the upfront cost of a fiber extruder may seem daunting, it can pay off in the long run by significantly reducing your filament expenses. Additionally, experimenting with different types of plastics opens up opportunities for creating unique blends and colors, giving them a personalized touch.

Filament bulk purchases: Saving money through bulk orders

If you find yourself frequently using a specific filament type, purchasing in bulk can lead to substantial savings. Many fiber manufacturers offer discounts or wholesale prices for larger orders. By planning ahead and estimating your fiber consumption, you can take advantage of bulk purchase options. However, ensure that you have adequate storage to keep the filaments in optimal conditions to maintain their quality over time.

Exploring alternative materials: Cheaper options beyond traditional filaments

While PLA, ABS, and PETG are popular choices, there is a vast array of alternative materials that can be both cost-effective and suitable for specific projects. For example, TPU (Thermoplastic Polyurethane) filaments provide flexibility and are often less expensive than ABS. Wood-infused filaments offer a unique and affordable way to add a natural aesthetic to them. Additionally, materials like HIPS (High Impact Polystyrene) can be used as support structures and are generally more affordable than traditional soluble supports. Exploring these alternative materials can open up new possibilities while keeping costs under control.

Optimizing settings: Maximizing filament efficiency for cost savings

Fine-tuning your print settings can have a significant impact on fiber usage and, consequently, your budget. Adjusting parameters such as layer height, infill density, and print speed can optimize print quality while reducing material consumption. Experimenting with different settings and finding the right balance between quality and efficiency can result in substantial cost savings over time. Additionally, using support structures only where necessary and employing advanced printing techniques like vase mode can minimize fiber waste, stretching your budget even further.

Post-processing techniques: Cost-effective finishing and polishing methods

Post-processing is an essential step to enhance the appearance and functionality of 3D prints. However, traditional methods like sanding and painting can be time-consuming and expensive. Opting for cost-effective alternatives, such as using a heat gun to smooth surfaces or employing acetone vapor baths for ABS prints, can achieve impressive results without breaking the bank. Additionally, exploring free or low-cost post-processing techniques like friction welding or using epoxy putty for repairs can save you money while maintaining the integrity of your prints.

Maintenance and storage tips: Preserving filaments for extended usability

Proper maintenance and storage of filaments can prolong their shelf life and ensure optimal print quality, ultimately saving you money. Filaments are hygroscopic, meaning they absorb moisture from the surrounding environment, leading to poor print quality and failed prints. Invest in airtight storage containers or vacuum-sealed bags and include moisture-absorbing desiccant packs to keep filaments dry. Regularly inspect fibers for signs of moisture damage and store them away from direct sunlight and extreme temperature fluctuations. Taking these precautions will help you avoid fiber waste and the need for frequent replacements.

Conclusion: Embracing budget-friendly 3D printing for creative endeavors

In conclusion, 3D printing doesn’t have to be a costly endeavor. By implementing these strategies and tips, you can save money on fibers and materials without compromising the quality of your prints. From understanding fiber types and comparing prices to exploring alternative materials and optimizing print settings, there are numerous ways to make 3D printing more budget-friendly. Additionally, embracing eco-friendly practices, such as using recycled materials and producing your own fibers, not only saves money but also contributes to a sustainable future. So, unleash your creativity and embark on your 3D printing journey without breaking the bank!

Hi Boox Popular Magazine 2024

Hi Boox Popular Magazine 2024