Sealing machines are one of the best-known versatile devices. They are primarily used in various industries to seal foil seals on jars prior to capping. To prevent jar contents from spilling, you can use a foil sealing machine. Not only this but you can also use this device to package various types of jars and bottles.

The aluminum foil sealing machine uses the electromagnetic induction principle. This method is top-rated to obtain hermetic seals on the bottle and jar mouth. Whether they are simply mason jars or unique candle jars, the technique works well for all.

In this guide, you will learn all the important aspects of a basic aluminum foil sealing machine. Read on to learn how amazingly this device works!

Introduction to Aluminum Foil Sealing Machine

Since aluminum foil induction is one of the principal sealing equipment, we use aluminum foil to seal the containers. Many top packaging pouches manufacturers also use this to seal their pouches. This device is also known by different names such as:

- Aluminum can sealer machine/equipment

- Aluminum sealer machine/equipment

- Aluminum can seamer machine/equipment

These packaging machines hermetically seal the glass and plastic jars, bottles, cans, and whatnot. People prefer induction sealing as it significantly extends product shelf life. Not only this but the sealing machine also prevents leaks, and, most importantly, provides tamper-evident seals.

You can also get handheld, electrically powered, and manual aluminum foil induction can seamer machines for sealing different closure sizes.

Uses of Aluminum Foil Sealing Machine

The basic use of the aluminum foil sealing machine is to create a hermetic seal on different types of products. Due to this mechanism, this device is important for many industries.

Some of the main and most industries using aluminum foil sealing machines are food, petroleum, pesticide, chemical, pharmaceutical, and cosmetics among others.

The machine is an essential component to these industries because of its capability of achieving the highest quality of sealing. As a result, it increases the shelf life of countless products. The ability to seal tightly also increases the product safety while it is within the jar or bottle.

You can also use this sealing machine to print labels on the seal. This is an important aspect of branding and easy identification. Additionally, some of the sealing machines not only place the seals but also include the cap while carrying out the sealing process.

Main Features of Aluminum Foil Sealer Machine

A modern aluminum foil sealer machine is full of features. Some of the main features are:

- Stainless steel is used as the main material for constructing the foil sealing machine.

- The device is compliant and perfectly meets the main pharmaceutical as well as food quality standards. This includes cGMP as well.

- It comes with a high-quality variable drive motor along with the sealing speed controller.

- The operating efficiency of the aluminum foil sealing machine is very high. As a result, you get a stable seal.

- The device also features an automatic induction sealer. Such a package seems very affordable as compared to its benefits.

- This sealing machine is capable of producing a composite aluminum material. The material is ideal for sealing purposes.

Benefits of Aluminum Foil Sealing Machine

If you are someone who never had the chance to use the aluminum foil sealing machine, the following benefits will surprise you!

Have a look below:

- The incorporation of high-quality stainless steel as a construction material results in extremely high durability.

- The machine has a variety of drive motors hence, the sealing process is fast and efficient.

- The machine is completely automatic. Also, it is stable, and able to seal a number of bottles/jars in a short period.

- Last but not least, the sealing device produces composite aluminum foil which is the best for sealing purposes.

Basic Working of Aluminum Foil Sealing Machine

As we already know, the aluminum foil sealing machine totally depends on the electromagnetic induction principle. With this point in mind, read the following step-by-step guide. It revolves around the electromagnetic induction method.

Step One: The Machine Preparation Stage

The first and the most important step is to ensure the machine is in proper working condition. Make sure the device is all clear and the lubrication fluid is in place. Also, every machine part is in the right order.

Additionally, load the sealing material onto the machine hopper for immediate access. In the general case, you will load all the sealing materials. This includes aluminum foil, paper board, and heat sealing layer.

Once done, it’s time to power on the machine and let the sealing operations begin.

Step Two: The Sealing Material Preparation Stage

At stage two, the foil sealing machine will automatically pick the sealing materials. It will pick one material at a time, and not all together.

A typical induction layer is one that has multiple layers. These layers consist of aluminum foil, paper board, and heat sealing layer. Paper board is the first layer and it will be on top of the seal. Specifically, facing the container cap.

If you wish to have easy access or easy removal of the container seal, go for spot glue on the cap.

Now comes the second layer which is wax. This wax will function as the bonding material between the paper board and the aluminum foil. The third layer will be the aluminum foil. You will laminate the foil onto the bottom layer of the seal.

This bottom layer can either be the heat sealing layer or it can also be a polymer film.

Step Three: Placing the Seal on the Cap

Exclusively depending on the type of foil sealing machine, you have the right to decide either to place the seal on the container first or the cap.

In the current case, we will recommend you to place the seal on the cap first, prior to placing it on the container.

Step Four: Placing the Seal on the Container

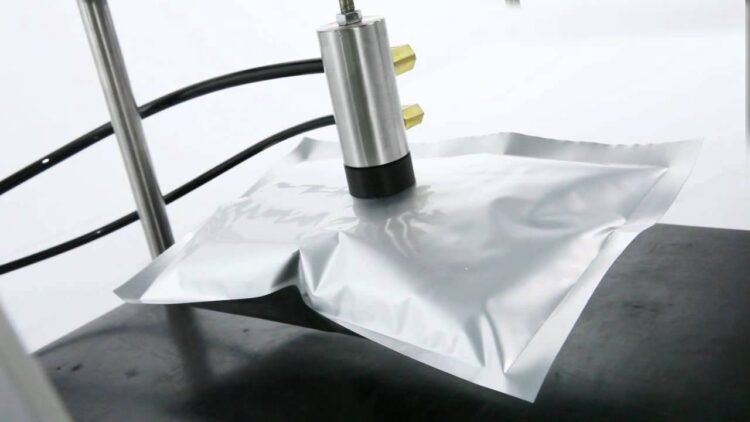

To place the seal on the container, complete the process with the content passing on a conveyor belt present under an induction coil. The sealing machine will place the cap complete with the seal onto the container, as it passes.

The induction coil will emit an oscillating electromagnetic field. The purpose of this field is to heat the aluminum foil due to eddy current. The second layer of wax will start to melt. It will then absorb into the paper board. As a result, the seal from the cap will be released.

Also, the heat sealing layer or the polymer film will also melt. It will then flow onto the container lips.

Step Five: The Cooling Process

In this step, you will pass the container through the cooling system. This system of the container is present on a conveyor belt of the sealing machine. As the container cools down, the molten polymer will create a bond with the container. As a result, you will get a hermetic seal.

This process is completely safe. Plus the container, as well as its contents, also remain safe.

Step Six: The Final Inspection of the Seal Strength

Now containers complete with the seals will go through an inspection or a seal test. This inspection will check the integrity of the seal. Further, it will ensure that the seal is strong enough.

You will use a seal strength testing machine to inspect the seals’ integrity. The last step after inspection will be packaging and storage of the sealed containers, in readiness for transport.

Conclusion

Well, we assume you are now a foil sealing machine expert. You can comfortably handle the sealing machine properly without any hesitation. With this detailed information at hand, you should also be able to buy a reliable aluminum foil sealing machine.

Do not wait any longer. Get in touch with the best supplier such as Levapack can sealers and order your custom aluminum foil sealing machine today! Click here to visit their website.

Read Also:

The Environmental Benefits of Using Aluminum Food Containers

Hi Boox Popular Magazine 2024

Hi Boox Popular Magazine 2024